Products & Services

Product Description

How Does the ESD Protection Work?

The ESD property is not inherent to plain polypropylene. It is achieved by incorporating carbon or other conductive additives into the plastic resin during the manufacturing process. This creates a permanent conductive network throughout the entire sheet, giving it consistent Surface Resistivity and Volume Resistivity within a safe range.

Surface Resistivity: Typically in the range of 10^6 to 10^9 ohms/sq (according to standards like ANSI/ESD S20.20).

10^6 - 10^8 ohms/sq is considered Static Dissipative (safely drains charge).

10^9 - 10^11 ohms/sq is considered Antistatic (resists triboelectric charging).

This ensures that any static charge is dissipated slowly and safely to ground, rather than building up and creating a spark.

Common Applications

This material is ubiquitous in industries where electronics are manufactured or handled:

ESD-Safe Packaging: Boxes, clamshells, and sleeves for shipping and storing PCBs and components.

Worksurface Mats: Used to line workbenches in electronics assembly areas.

Dividers & Liners: Used inside storage bins and shelving (e.g., ESD-safe versions of Kanban systems) to compartmentalize and protect parts.

Racks & Trays: Fabricated into custom trays for automated handling and transport during the manufacturing process.

Shipping & Logistics: As durable, protective layer sheets within larger containers to separate and shield sensitive products.

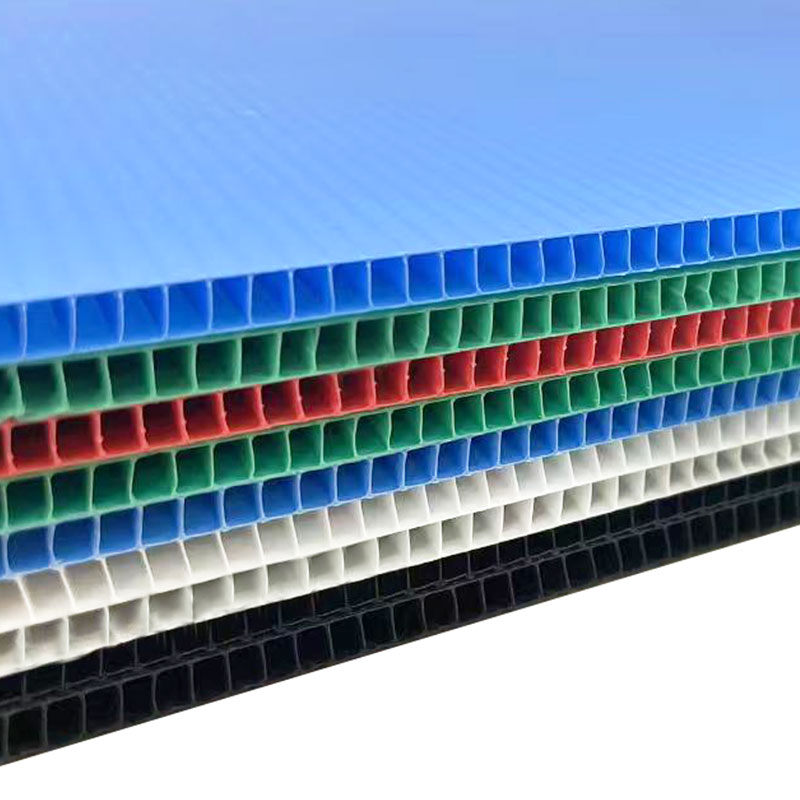

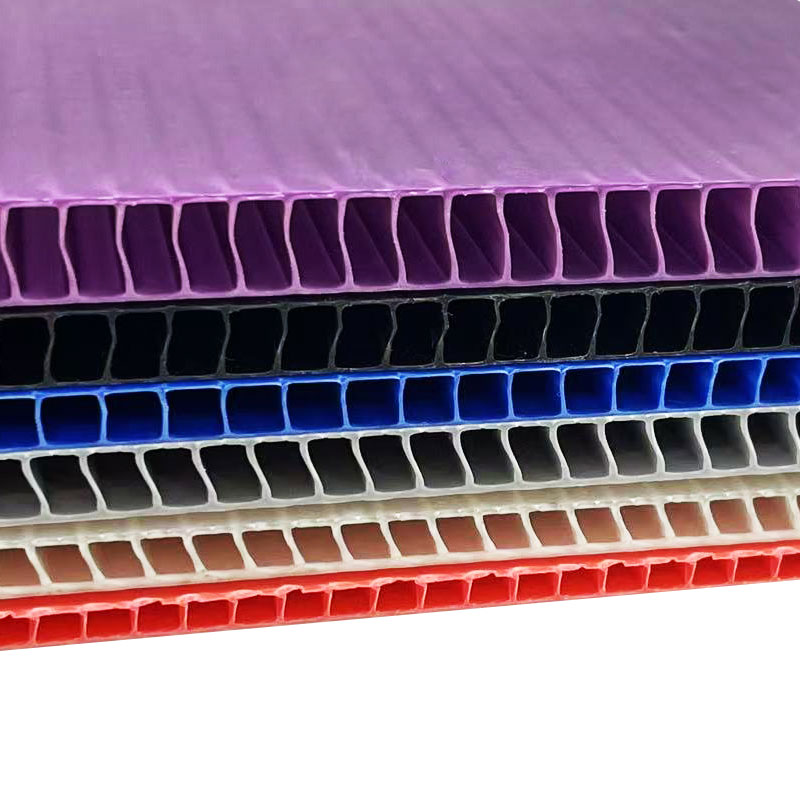

Product Show

Message

Products Recommended

Chat Online